Hup had zoning and slew encoders turned on. Encoders would pair, Zero slew angle would accept and zones worked after being set. Normal operation would resume, but the crane would not slew after being shut down at the base (CCT/SCM computers powered off) and restarted after 10 minutes. Scrolling through the menu zero angle wasn’t present. Operator reset zero angle and slew movement was regained until crane was powered off at the base.

1)Turn off Slewing encoder option, This will tell the CCT to not look at the encoder, the crane regained slew.

2) Check slewing encoders for faults. In this case, the main slewing encoder would flash a single red light.

3) replace slewing encoders and pair

4) turn on slewing encoder option

5)Set zero angle and zones

LMI screen won’t work. Says needs update

When you have the cab plugged in the LMI screens won’t work properly. If you don’t have a cab hooked up the screen in the electrical panel at base of crane will work just fine. If you have the cab plugged in the screen at the base of the crane will say needs up date. For the one in the cab to work correctly you need to unplug the the one at the base of the crane. The plug to unplug it is behind the screen.

Crane code for teach-in

51,52When teach-in T99 crane its limits you have to put your tech code into the remote. If you try to use the cranes password that screen will stay locked. You can use crane code to dismantle and erection.

Crane will not hoist

Crane will not hoist up or down. No fault on CCS, but drive shows “E OC” which means motor overcurrent.

Manually release brake, and fault changes to “E 68″ brake switch malfunction. This indicates that the drive is seeing an over current fault, and the brake is typically not the culprit. Verify brake is being released by drive, and verify brake disk adjustment. With brake manually released, the drum spins freely.

Found contactor K466M (motor heating) was stuck in the activated position. Could not release the contactor coil (contacts may be welded) Switched off Q407F, and crane hoists normally.

As drive would send voltage to motor to work, but motor was requiring more voltage than the drive was sending to rotate because it was heating the motor additionally. Drive would stop due to this ‘over current” sitauation.

T85A in Dismantle wouldn’t hoist K944A

Hoist Drive was saying it was RDY but had no functions on hoist. Erection aid was saying >30 dregrees and not =to 0 degrees went into the wire schematics and found out that K944A needs to be activated to get =0 degrees K944A was getting voltage but coil was to weak to pull in. Activated K944A and erection aid was now reading =0 degrees

Hup Slew limit

On the Hup cranes we have slewing limit switches. We also have the option slewing encoders and the collector option.

• The limit switches (S610S and S615S) work only when the options are not enabled (angle, Top Zone and collector)

• If the top zone option is enabled we must also enable the angle option. When the 0° angle is enabled, the slewing movement cuts will be made by the encoders (B260N and B261N) and from 0°.

• If the collector option is activated, we bypass the limit switches, so there is no more cutting of the three turns in the slewing

Slewing Motor Encoder Failure (internal short)

If the motor encoder is internally shorted, the drive may not operate in partial open loop as it tries to protect itself. If this is the case, unplug the 2 connectors from the slew drive and reprogram parameter 90.46 to Force Open Loop.

The drive will also need to be told not to look for the Encoder.

- Parameter 75.12

- Switch from 2 to 0

- Save

In this specific case, operator experienced a separate fault showing “Transition 4” . Here is the link to that fault.

https://service.rockymtncranes.com/2024/01/12/transition-4/

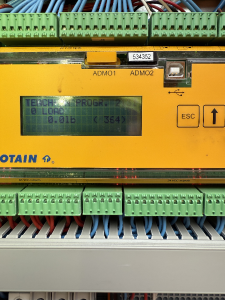

Paint Codes for Potain Tower Cranes

Igo T85 keeps shutting off when the hook is near upper limit

Looking in the fault stack, 1-400-711 showing in the fault stack and BrF on the hoist drive this was the first fault. The second fault was 1-230-007 load sensor wiring problem.

It would always have the 400 code then the 230 code. Need to always look past the first fault code

Checked and all drives were shutting off, not just the hoist drive. Tomas says if all drives shut off, its not the brake but rather the brake fault is a result of another failure.

Near the upper limit, the 0 load was showing 230 pions. In the manual, the crane wants between 1150-1350 pions. As a result, the crane would fault and shut off all drives and the fault 1-400-711 was a result of shutting off the brake contactor and the 230 code from the processor shutting down the drives.

The teach-in portion of the manual tells the tech to lower the block all the way to the ground raise until the hoist cable is in the middle of the drum. This load cell was only reading 364 pions.

Replaced the load cell and redid the teach-in. The crane was only reading 936 pions at 0 load. Although lower than what the manual specified, it is within the operating range of the crane.

Hup 40-30 after swinging shudders to a stop

Check the swing motors o make sure that mechanically there was no failure and the brake are physically releasing.

Update crane CCS software and update each drive

BST21-284-B – New CCS version 1.8.21 and updating of the HUP variable frequency drives_EN (2) (1)

**NOTE** This will delete the serial number and load cell and encoders