Jumper 2 wires together

Jumper 2 wires together

When trying to start crane, the PLC and the load sensor were not turning on. The top light on this device was flashing red.

This is an electronic circuit break. Found the short, and corrected. The red light can be pushed to reset.

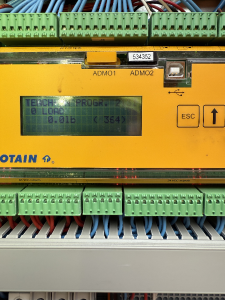

The crane lost eception with the remote and shutoff. The operator tried to restart and it would not restart. The operator took a picture of the following code.

The code 0x 0400 means the remote is asked to start (restart), but there is a function being applied at the same time. The operator was in mid-swing when it lost reception and the operator did not release the joystick when he tried to restart. The picture shows this.

Customer called and crane won’t swing. Crane will hoist and trolley, but no swing. Error code “E 705”. Slowing gear safety device. Thaddeus was able to FaceTime with customer and found slew drive circuit breaker was tripped.

Crane will not hoist up or down. No fault on CCS, but drive shows “E OC” which means motor overcurrent.

Manually release brake, and fault changes to “E 68″ brake switch malfunction. This indicates that the drive is seeing an over current fault, and the brake is typically not the culprit. Verify brake is being released by drive, and verify brake disk adjustment. With brake manually released, the drum spins freely.

Found contactor K466M (motor heating) was stuck in the activated position. Could not release the contactor coil (contacts may be welded) Switched off Q407F, and crane hoists normally.

As drive would send voltage to motor to work, but motor was requiring more voltage than the drive was sending to rotate because it was heating the motor additionally. Drive would stop due to this ‘over current” sitauation.

Looking in the fault stack, 1-400-711 showing in the fault stack and BrF on the hoist drive this was the first fault. The second fault was 1-230-007 load sensor wiring problem.

It would always have the 400 code then the 230 code. Need to always look past the first fault code

Checked and all drives were shutting off, not just the hoist drive. Tomas says if all drives shut off, its not the brake but rather the brake fault is a result of another failure.

Near the upper limit, the 0 load was showing 230 pions. In the manual, the crane wants between 1150-1350 pions. As a result, the crane would fault and shut off all drives and the fault 1-400-711 was a result of shutting off the brake contactor and the 230 code from the processor shutting down the drives.

The teach-in portion of the manual tells the tech to lower the block all the way to the ground raise until the hoist cable is in the middle of the drum. This load cell was only reading 364 pions.

Replaced the load cell and redid the teach-in. The crane was only reading 936 pions at 0 load. Although lower than what the manual specified, it is within the operating range of the crane.

Check the swing motors o make sure that mechanically there was no failure and the brake are physically releasing.

Update crane CCS software and update each drive

BST21-284-B – New CCS version 1.8.21 and updating of the HUP variable frequency drives_EN (2) (1)

**NOTE** This will delete the serial number and load cell and encoders

1917.46(a)(1)(ii)

The accuracy of the load indicating device, weight-moment device, or overload protection device shall be such that any indicated load (or limit), including the sum of actual weight hoisted and additional equipment or “add ons” such as slings, sensors, blocks, etc., is within the range between 95 percent (5 percent underload) and 110 percent (10 percent overload) of the actual true total load. Such accuracy shall be required over the range of daily operating variables reasonably anticipated under the conditions of use.

Hoist drive failed. Instructions for drive replacement are in the folder, however it is required to add +24 vdc to DQ+. This applies power to the hoist brake control relay.

See attached schematic. Typically, the dotted lines are optional, but this is required.

Here are the screenshots, should the display fail