HDT 80 hoist stopped working, cannot hear the brake releasing but contactor was pulling in lower left wire on rectifier was loose

HDT 80 hoist stopped working, cannot hear the brake releasing but contactor was pulling in lower left wire on rectifier was loose

This is only for the Upper and Lower hoist limits and the Inner and Outer Trolley Limits

—– Limit calibration —–

With machine in work,

press the radio control buttons A and D simultaneously for at least 5s until the radio control buzzer sounds.

At this point the machine goes into calibration mode and the radio control screen changes showing the current maximum and minimum limits.

It is possible to move the lifting and trolley axes WITHOUT LIMITATION to bring them manually to the maximum and minimum positions.

Once the limit position has been reached, by keeping the corresponding button pressed for at least 3s, the quota (minimum or maximum) will be fixed to the current position of the axis

and to the value displayed by radio control.

The keys are assigned as follows:

– key A for minimum lifting limit (LOWER LIMIT CLOSEST TO GROUD)

– key B for maximum lifting limit (UPPER LIMIT CLOSEST TO JIB)

– C key for minimum cart limit (INNER TROLLEY LIMIT)

– D key for maximum cart limit (OUTER TROLLEY LIMIT)

The LEDs positioned above the keys indicate whether the limits calibration has been carried out (LED on steadily) or not (LED off), respectively at the minimum and maximum lifting and trolley levels.

——————-

Tried using Crane CCS code to get into maintence mode and it remains locked.

Must use technican CCS code to get to that menu

See attached for Access rights for either Crane code for Technican Code

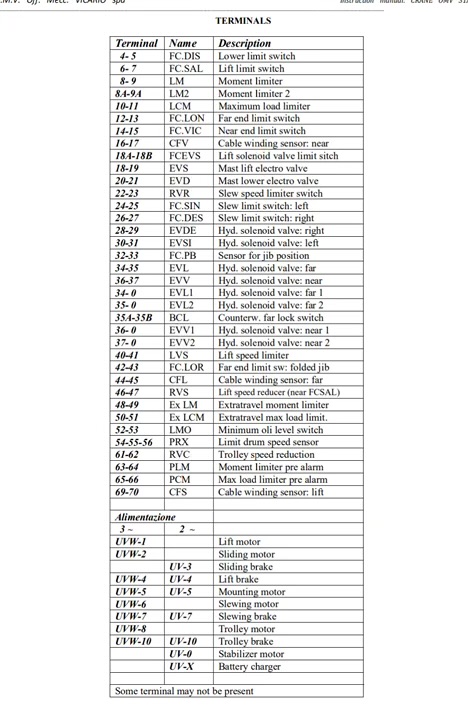

Here is a list of limit switched and what to do to jumper them.

Went to start to tower up and moved toggle switch on remote to the right. Didn’t hear the normal “whine” of the hyraulic pump. It ended up tripping the breaker Q940M. Flipped the toggle back and forth a couple times to get it to work and it didn’t. Motor was VERY HOT

Took motor off from pump with the 4 allen screws. Flipped the toggle a couple times and it broke free and ran

Re mounted motor and it worked like a champ

Customer stated when cabling down with load the hoist would kick out seem to be more frequent when the weather was bad opened up panel above electrical panel to check out dynamic breaking resistors and found one bolt missing a nut replace nut and put back together

Hoist

hoisting

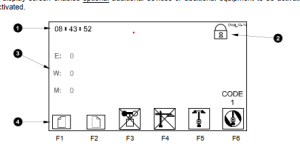

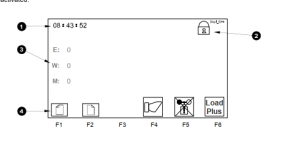

Turn Dianostic key in Side panel

Enter Code on Screen

Month+Day+Hour+Minute

You have one minute to enter code before it changes to the next minute

Hit F6 for Set Screen

Push and HOLD for 3 Second F3

This should remove or add X through the Wind Speed Senor

You can then hit F2 to go to next page to change units

You can then hit F2 again to change warning and Load Plus

Also is saved in Dropbox under T85

Swing motor

Swing motor parts diagram is also attached

SERVICE+GUIDE-GS-2022-001-2 (1)