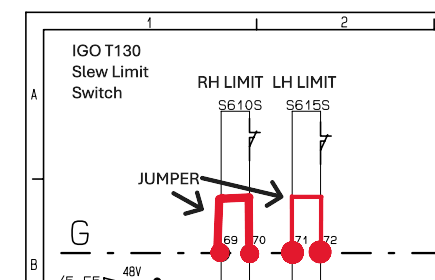

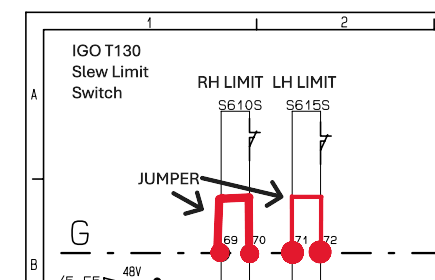

This is the wiring that needs to be jumped in order for the operator to untwist the power cords

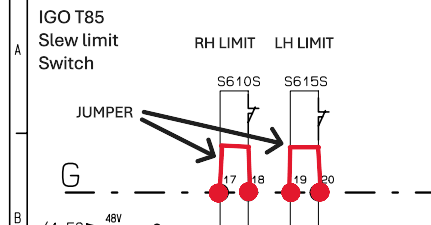

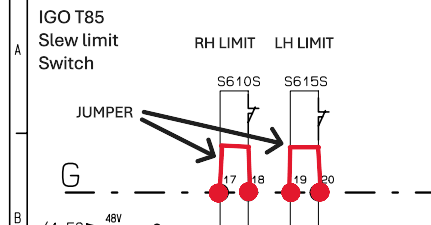

This is the wiring that needs to be jumped in order for the operator to untwist the power cords

Hoist Drive was saying it was RDY but had no functions on hoist. Erection aid was saying >30 dregrees and not =to 0 degrees went into the wire schematics and found out that K944A needs to be activated to get =0 degrees K944A was getting voltage but coil was to weak to pull in. Activated K944A and erection aid was now reading =0 degrees

Looking in the fault stack, 1-400-711 showing in the fault stack and BrF on the hoist drive this was the first fault. The second fault was 1-230-007 load sensor wiring problem.

It would always have the 400 code then the 230 code. Need to always look past the first fault code

Checked and all drives were shutting off, not just the hoist drive. Tomas says if all drives shut off, its not the brake but rather the brake fault is a result of another failure.

Near the upper limit, the 0 load was showing 230 pions. In the manual, the crane wants between 1150-1350 pions. As a result, the crane would fault and shut off all drives and the fault 1-400-711 was a result of shutting off the brake contactor and the 230 code from the processor shutting down the drives.

The teach-in portion of the manual tells the tech to lower the block all the way to the ground raise until the hoist cable is in the middle of the drum. This load cell was only reading 364 pions.

Replaced the load cell and redid the teach-in. The crane was only reading 936 pions at 0 load. Although lower than what the manual specified, it is within the operating range of the crane.

1917.46(a)(1)(ii)

The accuracy of the load indicating device, weight-moment device, or overload protection device shall be such that any indicated load (or limit), including the sum of actual weight hoisted and additional equipment or “add ons” such as slings, sensors, blocks, etc., is within the range between 95 percent (5 percent underload) and 110 percent (10 percent overload) of the actual true total load. Such accuracy shall be required over the range of daily operating variables reasonably anticipated under the conditions of use.

Crane starts, but will not swing. the Green Square is flashing on bottom right of LMI. Swing drive has 3 fault codes, AFE1 AFE2 and FBA A Missing.

For AFE! and AFE2 see link.

https://service.rockymtncranes.com/2022/09/07/afe1-and-or-afeb-faults-on-start-up/

Replace the memory stick, and had to force the K600M to stay active for complete download of the memory stick to the drive, and then restart crane. Crane swings and weathervanes properly.

Was trying to tower up and let Jib retaining rope out. Toggle on my remote was to the right on mast. Hydraulic motor would not come on and wasn’t able to let out the Jib retaining rope. Breaker Q940M was not tripped. Looked at my Erection aid and where S916S & S918S was just —- Which it should have been reading S916S. Switches were good, checked B911N (Inductive control detector of retaining winch) will also put —- if it’s not reading correctly. Had 48V at G27. K916A was not Acted on. Had 48V at K916A. Wiggled contactor and orange plunger on K916A was Acted on. Erection Aid was reading S916S. Hydraulic motor and Jib retaining rope started working. Need to probably replace K916A

After telescoping to the correct height, went to raise jib to 0 degrees, and all the drives would shut off. It would go down, but wouldn’t come up. Tomas said on “SOME” T85’s and “SOME” generators (pre-emission), the jib reatining winch can trip the phase detector. Jumper the 2 red wires together in 1 slot (11 & 14), and bypass phase detector. Once operation is complete move wires back.

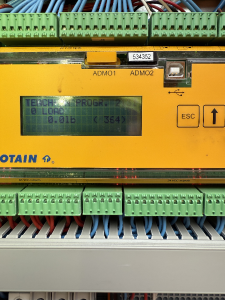

Processor shows the following

Remote shows the following

Crane may think it is in “High Height” (H3) and 4 parts of line are selected (DM). In H3 (High Height) crane must be operated in 2 parts of line (SM), not enough line on hoist drum.

Make sure S917S is adjusted properly. It is the limit box on the end of the jib retaining motor.

If the switch is adjusted properly, and not activated (Normally Closed NC), check Fault Stack (3-4-1)

Most recent fault is that the CanOpen Module is not detected. Verify by checking Can Module Inputs on processor (3-9-1)

Check for RUN light on Can Module (U213X)

If the RUN light is not on check T131F (the +24VDC transformer) for power. If the DC OK light is not on, the transformer is not working.

Check Circuit Breaker Q133F to make sure transformer is being supplied 480 VAC. If breaker is tripped and cannot be reset, replace transformer.

If RUN light on, but flashing, it is not communicating with the processor. It will still show U213X as not detected. Disconnect H4, H5, H6 connectors on Can Hub (U237X)

These are the communication cables for the labeled drives and operate on the same CAN2 network. If the H3 disappears (may need to restart crane), plug each cable back in to determine which one (or more) may be the problem. The cable(s) may not be the only problem. It quit possibly could be the drive(s) as well.

Here is the condensed version of the expanded troubleshooting tree.

Issue

AC/Heat unit not working

Cause

The AC unit not working can be caused by multiple problems, follow the procedures in the resolution notes to find out what is wrong with the unit, or if it need replaced

Resolution

TA23-450-C – Troubleshooting flow chart for the ultraview cab air conditioning system_EN

Crane was fully erected had jib retaining pin engaged and button pushed to validate crane. Switched it to C4 no functions switched it back to C3 got functions back. In erection aid S916S was flashing and S910S was flashing. Crane had a Jumper in between G25 and G27 Pulled jumper erection aid went from S916S flashing to S918S fixed which erection aid is reading jib retaining pin is locked. After switching to C4 S910S was still flashing need to switch back to C3 and put your toggle on your remote to mast and re validate jib retaining pin then switch to C4 then had all functions.