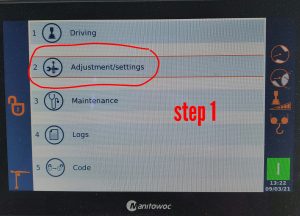

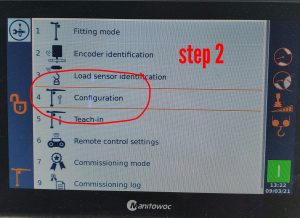

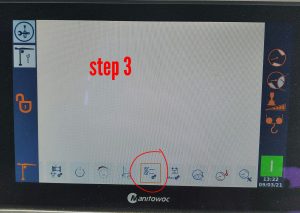

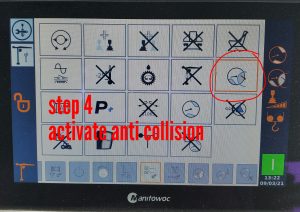

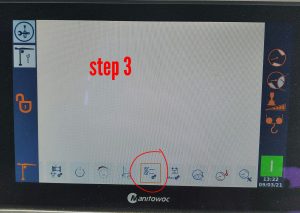

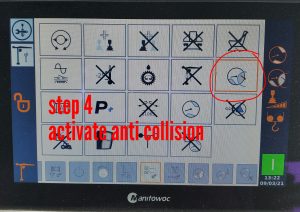

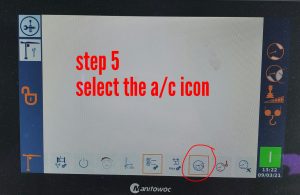

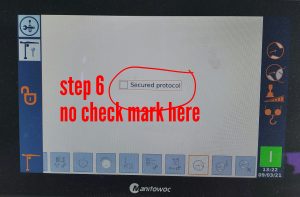

To activate the anti collision on the CCS.

To activate the anti collision on the CCS.

Generator would start and run on Starting Fluid though. Found faulty relay sending power to fuel shut off solenoid, but here is the bypass for emergency operation.

Locate Fuel Shutoff Solenoid

Remove 2 mounting screws and lift off solenoid

To shutoff generator, press down and hold the fuel shutoff cam lever

Make sure the light tower next to the control panel is assembled correctly .

Plug in Power and Network cable into the actuator to reprogram, and terminating resistor in bottom plug

Plug in CGW reader

Select Online and Network

Select CAN Valves

And then Valves again

This should then only display the name of the actuator you are plugged into.

Scroll down to Valve ID and press SET

Scroll to proper actuator name and press ENT. Then when prompted scroll to bottom and select 157BPVSK

When complete, replaced wires and connectors in their proper order and go back into valves and make sure all actuator functions are listed and there are no duplicates

Locate address key on the side of the remote

Remove key and insert into new remote, making sure it is in the right direction

Operator says fan not blowing and AC unit was not switching on. Had to reset circuit breaker Q362F

Turn multimeter to the V setting for voltage (If your meter differs, choose the V with the wave symbol and range to 500V)

Locate the G4 junction block on the right side of the control panel above the circuit breakers on the bottom. Install black lead from your meter into the green and yellow block

**CAUTION** only hold the red test lead by the plastic portion near the wire lead. You are checking high voltage and high amperage and injury could result.

Locate the filter in the right of the of the control panel. It is labelled C100F

Test voltage of L1 to Ground

Test voltage of L2 to Ground

Test voltage of L3 to Ground

Test voltage of L1 to L2

Test voltage of L2 to L3

Test voltage of L1 to L3

The top button is the start button (line with horn icon)

The bottom button is the horn only

The top button is the swing brake

The bottom button is the rope reeving change button

The toggle switch is for erection and work mode (to the left is jib, right is mast, center is work)

The red button is the emergency stop (its spring loaded and should pop back up after being pushed)

Top series of buttons is hoist

2nd from the top is trolley

3rd is swing

4th is travel